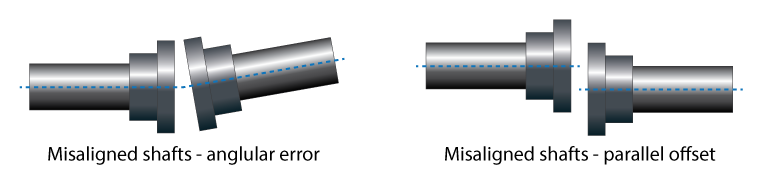

At ISS/Rotating Mechanical Solution (RMSC), we specialize in laser alignments that ensure your equipment’s optimum facility production and reliability. With our advanced Rotalign Ultra iS, we execute precision laser shaft alignments, essential for the proper installation, setup, and regular maintenance of your machinery. Our detailed reporting provides you with documentation of initial misalignments and the corrective actions undertaken, enhancing equipment operation and significantly reducing downtime and costly repairs.

Comprehensive Solutions for Optimum Facility Production

Our approach to pump alignment and motor pump alignment is designed to maximize facility production and reliability through accurate laser shaft alignment. By utilizing the Rotalign Ultra, RMSC delivers meticulous alignments with detailed reports for your records. Our expertise extends from initiating and annually verifying alignments on high-powered compression equipment in the oil and gas fields to maintaining critical equipment like fire pumps and chilled water pumps in urban buildings.

Laser Shaft Alignment with Live Trend

ISS/RMSC offers an advanced Live Trend feature for real-time adjustments to movable machinery under actual operating conditions. This innovative method involves monitoring the equipment over a set duration to gather crucial data on positional variations, including vertical thermal growth and torsional deflection. Our comprehensive analysis guarantees optimal alignment and performance, catering specifically to the dynamics of your operational environment.

This comprehensive strategy minimizes downtime and avoids expensive repairs, ensuring your facility’s productivity and reliability.

RMSC’s Approach to Laser Shaft Alignment

Our extensive experience and commitment to excellence underpin RMSC’s approach to laser shaft alignment. We begin with a thorough assessment to identify any underlying issues before alignment. By leveraging the latest electric motor alignment tools, we ensure maximum precision. Each alignment task is customized to meet the specific needs and specifications of your equipment, providing solutions that are as unique as your operational requirements.

Their process includes:

Thorough Assessment: Before alignment, a complete evaluation of the machinery is conducted to identify any underlying issues.

Advanced Technology Usage: Utilizing the latest laser alignment tools for maximum precision.

Customized Solutions: Each alignment task is tailored to the specific needs and specifications of the equipment.

Motor to Pump Laser Shaft Alignment Near Me

Preparing new equipment for optimal performance begins with pre-alignment before shipment and installation in the field. RMSC’s start-up/commissioning process includes a subsequent laser shaft alignment to ensure precision once the equipment is operational on-site. Baseline Vibrations Analysis data is collected at this stage to set the standard for ongoing equipment performance monitoring.

Electric Motor to Screw Compressor Laser Shaft Alignment

Our process for electric motor to screw compressor laser shaft alignment addresses the critical needs of high-powered machinery. After completing the cold alignment, we reposition the transmitter and receiver to both pieces of equipment to document thermal growth and torsional deflection. These measures are crucial for the subsequent hot alignment, ensuring your equipment operates at peak efficiency.

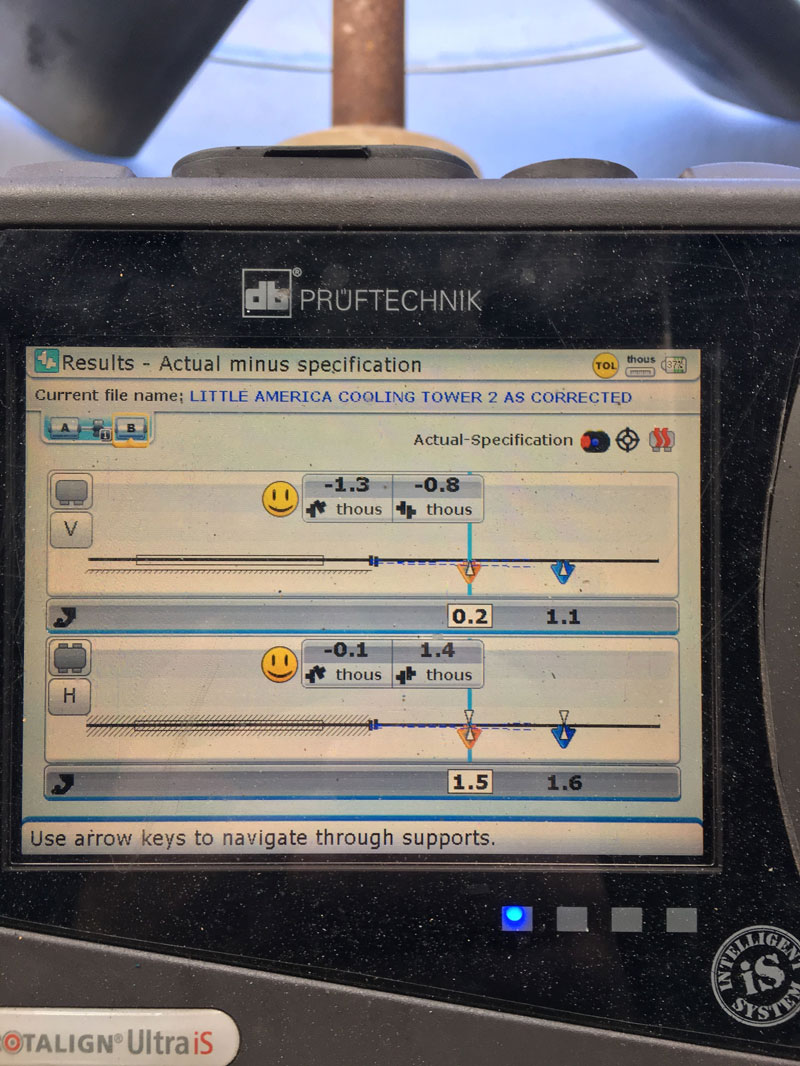

Cooling Tower Maintenance

The laser shaft alignment of electric motors to right-angle gear reducers is crucial for extending the life of all rotating components and reducing overall equipment vibration. RMSC’s precision alignment services ensure the longevity and efficiency of your cooling towers, contributing to the overall health of your facility’s mechanical systems.

EXPLORE THE WIDE VARIETY OF SERVICESINDUSTRIAL SERVICE SOLUTIONS PROVIDES

Industrial Service Solutions is your source for many industrial services, products, and information. Take a moment

to explore the other companies in the ISS family that are eager to serve you with unparalleled variety, expertise, and value.

Choose a service below to learn more about our capabilities and offerings. If you do not find what you’re looking for,

feel free to give us a call at 239.288.5230 or email sales@iss-na.com. We’re always here to help.

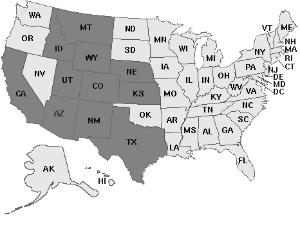

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states:

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states: