Vibration Analysis

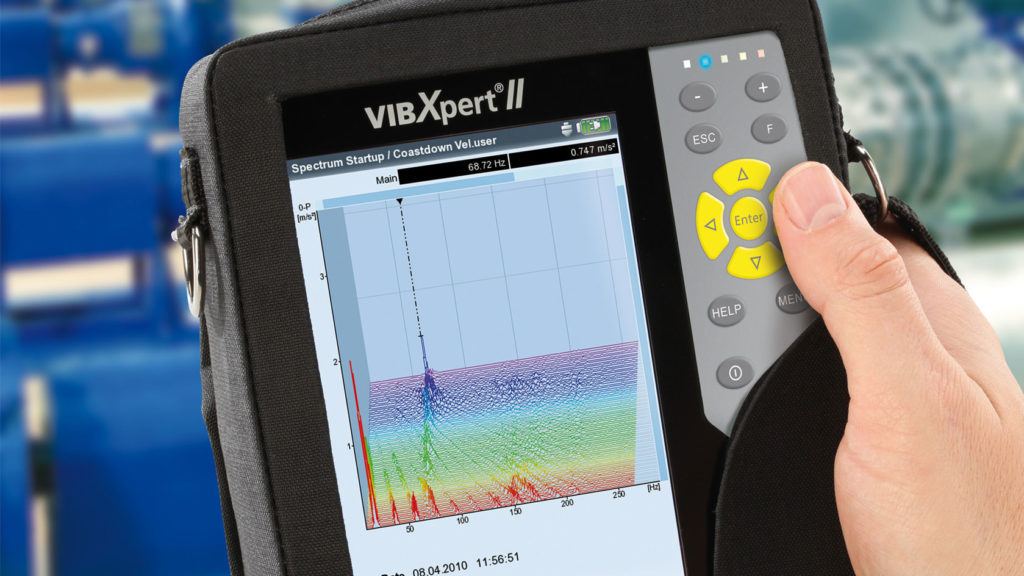

The Pruftechnik VibXpert data collector with OmnitrendSoftware is also utilized to perform vibration analysis on a multitude of equipment. Our technicians can analyze collected data and provide reports that identify problems in the very early stages of failure. Trending this data over periods of time is also a powerful tool, allowing our customers to schedule repairs, thereby avoiding downtime and costly emergency repairs.

Vibration Monitoring

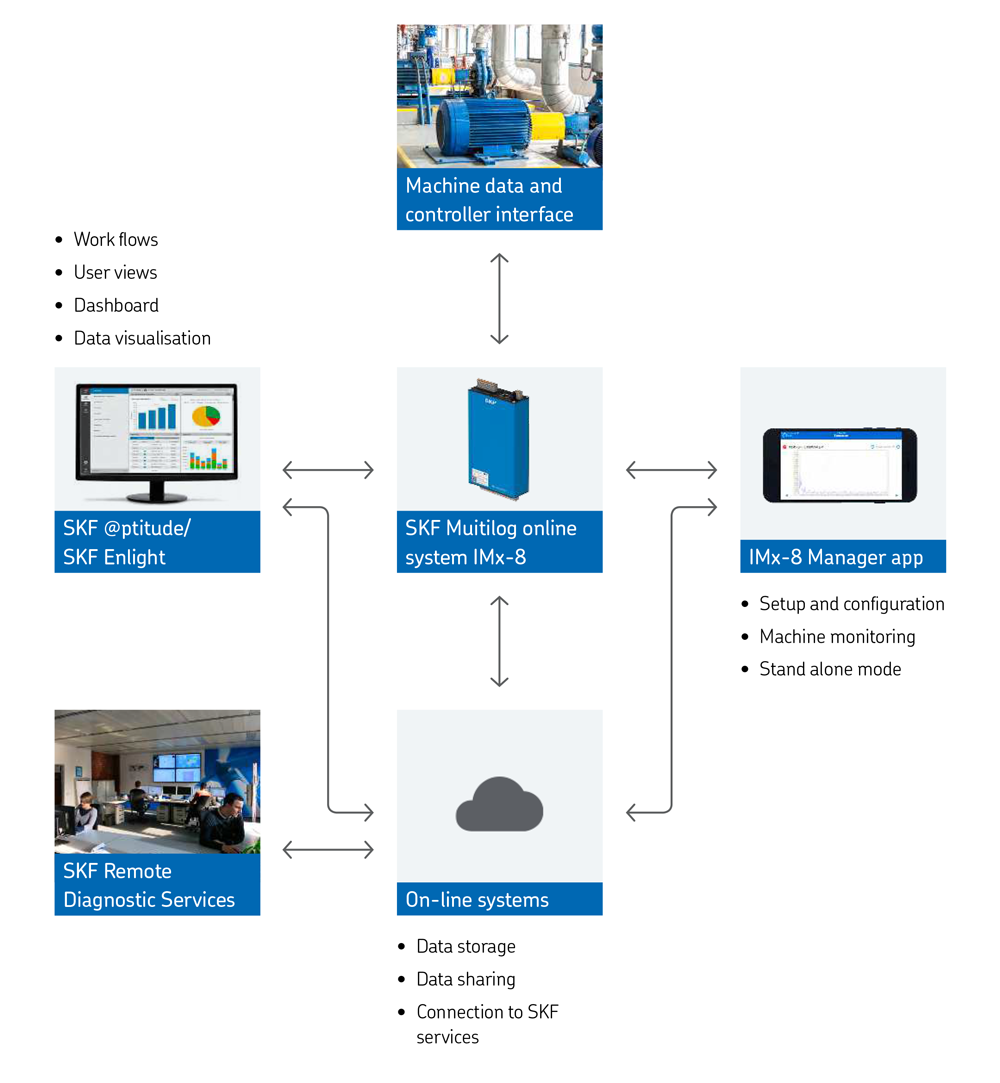

Vibration Monitoring is one of the most useful Condition Monitoring techniques available to maintenance technicians as early identification of problems such as Imbalance, Bearing Faults, Misalignment and Gear Tooth Mesh problems are critical factors in ensuring and extending the working life of machinery.

Rotating Mechanical Solutions use Vibration Monitoring to monitor the health of rotational equipment.

This involves the trending and analysis of certain machinery performance parameters to detect and identify developing problems before failure occurs, causing extensive damage. The detection and diagnosis of faults before they become a problem is obviously the most desirable way to maintain machinery. An effective condition-monitoring program will help to detect faults at an early stage such as when rolling element bearing defects are still minor and do not affect the performance of the machine. This allows time to analyze the problem while the machine stays online and production continues normally. This advance warning allows for planning of the repair at a convenient time.

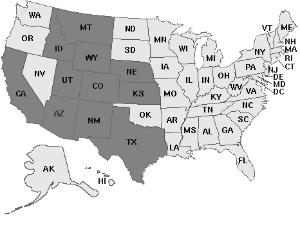

Rotating Mechanical Solutions Corp. proudly provides Industrial Equipment Solutions for our customers in the following states:

Rotating Mechanical Solutions Corp. proudly provides Industrial Equipment Solutions for our customers in the following states: