Click Here and Contact Us

24/7 EMERGENCY SERVICES

Maximizing Efficiency: Why Rotating Equipment Repair Services are Vital

The Key, to Keeping Operations Running Smoothly

Have you ever taken a moment to consider how those massive turbines create power or how those large pumps ensure a flow of water in your community? These are examples of machines that rely on maintenance and repair to function smoothly. It’s crucial to prioritize rotating equipment repair to keep these machines operating

Have you ever taken a moment to consider how those massive turbines create power or how those large pumps ensure a flow of water in your community? These are examples of machines that rely on maintenance and repair to function smoothly. It’s crucial to prioritize rotating equipment repair to keep these machines operating

Whether you work at a power plant, manufacturing facility or any industry that depends on machinery understanding the importance of rotating equipment repair is essential. This article will explore all aspects of this field from its definition to the trends in the industry.

Exploring Rotating Machinery and Its Importance

Rotating machinery consists of any equipment that uses rotating parts to perform its designated tasks. This category includes motors, pumps, turbines and compressors. These devices play roles in sectors such as:

- Power generation: Rotating machinery drives generators that produce electrical power.

- Oil and gas: These tools are crucial for extracting oil and gas from the ground and transporting them through pipelines.

- Chemical processing: Rotating equipment is essential, for mixing, separating and moving chemicals during manufacturing processes.

- Water treatment: These machines handle pumping, filtering and treating water for use.

- Manufacturing: Rotating machinery is crucial, for operating machines on production lines.

Rotating equipment plays a role in our lives ensuring the smooth operation of everything from energy generation to the goods we depend on.

Common Challenges with Rotating Machinery

Like any system rotating equipment is susceptible to wear and tear leading to a range of issues such as;

- Bearing problems: Bearings deteriorate over time causing increased vibrations and noise.

- Seal issues: Seals can develop leaks allowing substances into the machinery and causing damage.

- Alignment difficulties: aligned components can result in vibrations and premature degradation.

- Corrosion: Exposure to moisture and chemicals can cause metal parts to corrode, resulting in damage.

- Imbalance: Uneven weight distribution within the rotating part can lead to vibrations and reduced efficiency.

These challenges can lead to decreased efficiency, lower production output and costly downtimes. This underscores the importance of repairing rotating machinery. Ensure your machinery performs optimally!

The Importance of Repairing Rotating Equipment

Maintenance and timely repair of rotating equipment are crucial, for the following reasons;

- Uptime and reliability: maintenance and timely repairs help minimize downtime.

Make sure your machines work reliably.

- Cut down on costs: Regular maintenance and repairs can help your equipment longer saving you money on replacements.

It’s important to maintain your equipment, for safety, energy efficiency and compliance with regulations. Ignoring the upkeep of rotating equipment can lead to breakdowns lost production, safety risks and regulatory problems.

Investing in the repair of rotating equipment is crucial to keep your machines running extend their lifespan and reduce downtime.

The process of repairing rotating equipment involves tasks like disassembly and inspection by technicians to identify issues.

Rotating Equipment Repair Procedures Replacement of components: Worn out parts such as bearings or seals are replaced with ones. Repair or refurbishment: Damaged components like shafts or impellers can be. Restored to working order. Alignment and balancing: Adjustments are made to realign components and balance the rotating element to minimize vibration. Testing and commissioning: Once repairs are completed the equipment undergoes commissioning to ensure operation.

Preventive maintenance is key in the repair of rotating equipment.

Regular inspections, lubrication and cleaning help prevent issues from arising. Predictive maintenance techniques like vibration analysis and thermography aid, in detecting problems.

Reliability engineering plays a role, in enhancing the durability and lifespan of machinery by analyzing failure data and devising effective strategies.

There are companies offering repair services for rotating equipment ranging from shops to large corporations. The choice of service provider depends on factors such as the type of equipment requiring repairs and the seriousness of the problem.

Ensure that your machinery functions at its best, with the help of rotating equipment repair services. Avoid downtime by focusing on predictive maintenance.

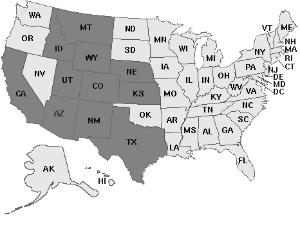

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states:

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states: