Industrial Motor Maintenance: A Guide to Maximizing Performance and Longevity

In industrial settings, maintaining motors is crucial for smooth operations and minimizing downtime. Industrial motor maintenance encompasses a variety of tasks aimed at ensuring the motors powering your machinery run efficiently, avoiding costly breakdowns. Whether you’re an engineer overseeing equipment or a business owner aiming to minimize operational disruptions, understanding the nuances of motor maintenance can help you extend the lifespan of your equipment and keep production lines moving seamlessly.

Why Regular Industrial Motor Maintenance Matters

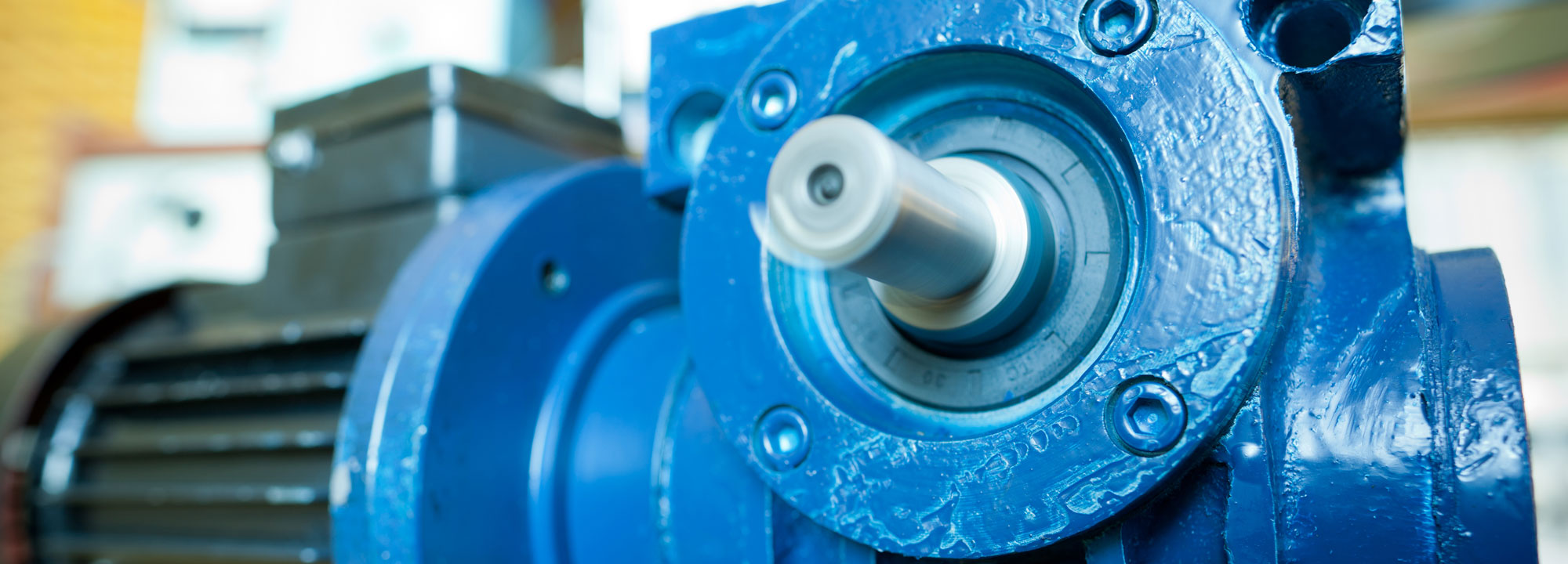

Industrial motors are the backbone of many industries. From manufacturing plants to processing facilities, motors are constantly at work converting electrical energy into mechanical power. Without proper maintenance, wear and tear can accumulate, leading to inefficiency, overheating, and ultimately motor failure.

A study by the Electrical Apparatus Service Association (EASA) revealed that 55% of motor failures stem from mechanical issues like bearing wear or misalignment. In contrast, electrical issues contribute to 23% of failures. These numbers highlight the need for both mechanical and electrical preventive maintenance to keep motors in top condition.

Core Components of an Industrial Motor

To maintain industrial motors effectively, you first need to understand the key components and how they contribute to overall motor performance.

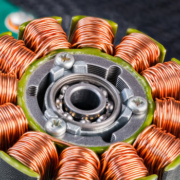

Stator: The stator is the stationary part of the motor responsible for creating the magnetic field that drives the rotor. In an industrial motor, the stator’s windings are critical for generating this field and ensuring smooth operation. Proper maintenance of the stator slots where the winding resides is essential for optimal motor performance.

Rotor: The rotor is the rotating component that produces mechanical movement. Bearings support the rotor, allowing it to spin freely. Over time, the rotor can experience misalignment, which causes vibration and impacts the motor’s overall efficiency. Regular inspection for balance and alignment issues is vital for motor health.

Bearings: Bearings are essential to reducing friction in the motor, enabling smooth movement. A worn or damaged bearing can cause the rotor to seize or generate excess heat, leading to premature failure. Lubrication and periodic replacements can extend the life of the bearings and consequently the motor itself.

Winding: Motor windings are key to generating the magnetic flux necessary for motor operation. Winding insulation can degrade over time due to temperature fluctuations, contaminants, and electrical stress, leading to electrical failure. Rewinding is a common solution when insulation is compromised.

Cooling Fan: The cooling fan is mounted on the rotor shaft, continuously cooling the motor during operation. Overheating can damage the motor windings, reducing the overall lifespan. Ensuring the fan is functioning correctly can prevent temperature-related issues.

The Importance of Motor Efficiency and Reducing Slip

Slip is the difference between the speed of the rotor and the speed of the rotating magnetic field produced by the stator. It’s a natural part of motor operation but should be minimized for greater efficiency. When slip increases, the motor must work harder, generating excess heat and reducing efficiency.

The Working Principle Behind Industrial Motors

Industrial motors work on electromagnetic induction, converting electrical power into mechanical energy. Here’s how it operates:

When a three-phase AC power source is applied to the stator windings, it creates a rotating magnetic field. As this magnetic field interacts with the rotor, it induces an electromotive force (EMF) in the rotor conductors, following Faraday’s Law of Electromagnetic Induction. This interaction causes the rotor to spin, generating mechanical movement. The rotor never quite reaches the synchronous speed of the stator’s rotating field, a difference known as slip, which is crucial for torque generation.

How Regular Industrial Motor Maintenance Extends Lifespan

- Routine Visual Inspection: Regular visual checks are essential for identifying early signs of wear and tear. Look for signs of excessive vibration, overheating, or unusual noise, which could indicate deeper issues like bearing wear or misalignment.

- Bearing Lubrication: Proper lubrication ensures smooth rotor movement and prevents excess friction, which can cause overheating and wear. Follow the manufacturer’s recommendations for lubrication schedules and types.

- Winding Testing: Testing the winding insulation for degradation can prevent electrical failures. Insulation testing, such as megger testing, can identify problems before they lead to costly breakdowns.

- Vibration Analysis: Excessive vibration is often a sign of rotor misalignment or bearing wear. Vibration analysis can help you identify and correct these issues before they cause permanent damage.

- Thermal Imaging: Heat is a leading cause of motor failure. Thermal imaging tools allow you to monitor the temperature of your motor components, helping you catch overheating problems early.

Common Causes of Motor Failure and How to Prevent Them

- Overheating: Overheating is one of the most common causes of motor failure. It can be caused by blocked ventilation, excessive load, or poor maintenance. Regularly checking the cooling system, including the fan, can prevent overheating issues.

- Electrical Faults: Electrical faults, such as winding shorts or ground faults, can result from insulation breakdown or voltage surges. Preventing electrical faults requires regular testing of the motor’s winding insulation and ensuring proper voltage levels are maintained.

- Vibration: Excessive vibration can cause damage to the rotor, bearings, and other motor components. This is often caused by misalignment, imbalance, or worn bearings. Regular balancing and alignment checks can minimize vibration-related issues.

- Bearing Wear: Bearings are critical for smooth rotor movement. Over time, they can wear out due to lack of lubrication or contamination. Replacing bearings at regular intervals and maintaining proper lubrication levels will help avoid bearing-related failures.

Maximizing Motor Lifespan Through Expert Maintenance

While routine maintenance can be handled in-house, partnering with experts like ISS/Rotating Mechanical Solutions (RMSC) ensures your industrial motors receive the specialized care they need. RMSC offers a range of services tailored to industrial motor maintenance, including rotor balancing, shaft alignment, and winding rewinding.

- Advanced Diagnostic Tools: RMSC uses advanced tools like vibration analysis and thermal imaging to diagnose potential motor issues before they lead to costly downtime. These tools can identify problems like overheating, misalignment, and rotor wear early, allowing for proactive maintenance.

- Customized Maintenance Plans: RMSC can create custom maintenance schedules tailored to your specific motor and operational needs. This ensures that your motors receive timely inspections and repairs, reducing the likelihood of unexpected breakdowns.

- On-site and Off-site Repair Services: Whether you need a minor adjustment or a full motor rebuild, RMSC provides both on-site and off-site services, ensuring minimal disruption to your operations.

Motor Maintenance Saves Costs and Reduces Downtime

According to research by the U.S. Department of Energy, proper motor maintenance can improve motor efficiency by 15-25%, leading to significant cost savings in industrial settings. Additionally, studies show that regularly maintained motors have an average lifespan of 15 years, while neglected motors may fail within just 5 years.

Motor Maintenance is Like Car Maintenance

Think of your industrial motor like a car engine. Just as regular oil changes, tire rotations, and brake checks keep your car running smoothly, routine inspections, lubrication, and alignment checks keep your motor in peak condition. Neglecting motor maintenance is like ignoring an oil change—you might get away with it for a while, but eventually, it will lead to costly breakdowns.

FAQs: Industrial Motor Maintenance

- Q1: What are the common signs of motor failure? Unusual noise, excessive vibration, overheating, and reduced efficiency are all common signs that your motor may be failing. Regular inspections can help identify these issues early.

- Q2: How often should industrial motors be maintained? It depends on the operational environment, but most industrial motors should undergo a detailed inspection every 6 to 12 months. High-use motors may require more frequent maintenance.

- Q3: Can motor maintenance improve energy efficiency? Yes, proper maintenance reduces slip, improves alignment, and ensures optimal performance, all of which can lead to significant energy savings.

- Q4: What is the most common cause of motor failure? Overheating and bearing wear are among the most common causes of industrial motor failure. Regular lubrication and ensuring proper cooling can mitigate these issues.

Ensure your motors are operating at peak efficiency and avoid costly breakdowns by partnering with ISS/Rotating Mechanical Solutions.

Call 303-594-7610, visit RMSCcolorado.com, or email service.0400@iss-na.com to schedule a consultation and keep your operations running smoothly.

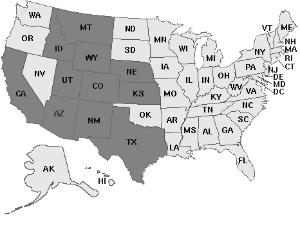

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states:

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states: