Click Here and Contact Us

24/7 EMERGENCY SERVICES

Industrial Electric Motor Repair: Signs and Maintenance Guidelines

Electric motor repair is essential for maintaining the efficiency and reliability of industrial systems. By recognizing early warning signs and knowing how often motors should be serviced, you can prevent costly downtime and extend the life of your equipment.

Signs That Your Motor Needs Repair

Identifying potential issues early can save time and resources. Here are the key indicators that your motor might need professional attention:

- Unusual Sounds

- What to Listen For: Grinding, screeching, or humming noises.

- Possible Causes: These noises often point to internal issues such as worn bearings or misalignment, which should be addressed quickly to prevent further damage.

- Excessive Vibration

- What to Watch For: Shaking or vibrations that are out of the ordinary.

- Possible Causes: Imbalance, misalignment, or bearing problems can cause vibrations that indicate a need for maintenance.

- Overheating

- What to Monitor: Motors running hotter than they should.

- Possible Causes: Overheating might be due to overload, poor ventilation, or electrical issues, signaling that it’s time to have the motor checked.

- Reduced Performance

- What to Notice: Decreases in motor speed, power output, or overall efficiency.

- Possible Causes: Mechanical wear or electrical faults can lead to reduced performance, which means the motor may need repair or servicing.

- Electrical Faults

- What to Check: Frequent tripping of circuit breakers or blown fuses.

- Possible Causes: Electrical problems, such as short circuits or insulation failure, require immediate investigation to prevent more severe issues.

- Visible Wear or Damage

- What to Inspect: Physical wear, corrosion, or other visible damage on the motor’s exterior.

- Possible Causes: These signs often indicate that parts of the motor need to be repaired or replaced.

- Unusual Smells

- What to Smell: A burning odor coming from the motor.

- Possible Causes: This could be a sign of overheating or electrical failure, both of which need urgent attention

How Often Should Industrial Motors Be Serviced?

Regular maintenance is key to extending the life of your industrial motors. The frequency of service depends on several factors, including how the motor is used and the environment in which it operates.

- Manufacturer’s Recommendations

- Why It Matters: Following the maintenance guidelines provided by the manufacturer is essential for optimal performance and longevity.

- Usage Patterns

- Why It Matters: Motors that run continuously or under heavy loads will require more frequent checks compared to those that operate intermittently.

- Operating Environment

- Why It Matters: Motors exposed to harsh conditions, such as dust, moisture, or corrosive substances, need more regular maintenance to avoid damage.

- Preventive Maintenance Schedule

- Why It Matters: Establishing a regular maintenance routine—whether it’s quarterly, semi-annually, or annually—helps catch potential issues before they lead to more significant problems.

- Condition Monitoring

- Why It Matters: Advanced monitoring techniques, such as vibration analysis and temperature checks, allow you to plan maintenance based on the motor’s actual condition, making it more effective.

Preventive maintenance is key in the repair of rotating equipment.

Regular inspections, lubrication and cleaning help prevent issues from arising. Predictive maintenance techniques like vibration analysis and thermography aid, in detecting problems.

Reliability engineering plays a role, in enhancing the durability and lifespan of machinery by analyzing failure data and devising effective strategies.

There are companies offering repair services for rotating equipment ranging from shops to large corporations. The choice of service provider depends on factors such as the type of equipment requiring repairs and the seriousness of the problem.

Ensure that your machinery functions at its best, with the help of rotating equipment repair services. Avoid downtime by focusing on predictive maintenance.

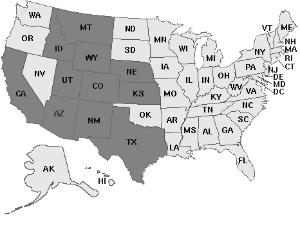

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states:

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states: