Call Us Today! 303-594-7610

Electric Motor Maintenance:

Ensuring Efficiency and Longevity

Maintaining your electric motor is a crucial aspect of facility management that guarantees optimal performance and reliability. Predictive and preventative maintenance combined with scheduled electric motor repair are key to preventing unexpected downtime and prolonging the equipment’s operational lifespan.

Lubrication: The Lifeline of Electric Motors

Bearing failure is responsible for an average of 75% of motor failures. Proper lubrication is the cornerstone of electric motor reliability. Manufacturer guidelines for lubricant types and schedules when considered with site specific conditions will optimize electric motor life.

Not only does this practice safeguard the motor’s intricate workings, but it also plays a pivotal role in comprehensive electric motor preventative maintenance program.

Bearing Replacement

Sustaining the Heartbeat of Electric Motors

Bearing health is synonymous with electric motor efficiency. Predictive maintenance is crucial and will extend bearing life through early detection and correction before the problem becomes a failure. Bearing replacement should be considered part of a comprehensive preventative maintenance program.

Timely replacement and expert installation arc crucial in electric motor repair services to prevent costly breakdowns and maintain operational continuity. If bearing replacement is scheduled prior to a failure often times no additional machine work or correction will be necessary. This operation can often be done by our highly skilled RMSC/Industrial Service Solutions field service crews on site.

Why is Cleanliness important in an Electric Motor?

Preventing Contaminant-Induced Failures

Electric motors are prone to accumulate contaminants that can impede electrical and mechanical performance. Regular cleaning is not just about aesthetics; it’s about performance and prevention.

Preventative maintenance programs that include a cleaning protocol for certain electric motor enclosure types particularly forced ventilation or filtered intakes will greatly improve the motor’s efficiency while also contributing significantly to the overall reliability and functionality of the electric motor.

Let RMSC/Industrial Service Solutions advise and assist with on site cleaning and maintenance for your critical assets.

Dynamic Balancing

The Equilibrium of Electric Motor Performance

The dynamic balancing of an electric motor ensures that it operates smoothly and efficiently. An unbalanced motor can lead to premature bearing failure ultimately causing down time. By including dynamic balancing in your preventative maintenance program, you ensure that your electric motor will perform at its peak performance with minimal unnecessary strain on components.

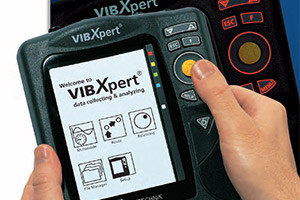

Contact the RMSC/Industrial Service Solutions field service department today for on site precision balancing . We have two VibExpert II by Pruftechnik portable balancing machines ready to assist.

Vibration Analysis

Vibration Analysis

Diagnostic tool for Electric Motor Reliability

Vibration analysis is a non-invasive diagnostic tool that plays a critical role in detecting issues within an electric motor before they escalate. By routinely analyzing vibration patterns, maintenance teams can identify misalignments, imbalance, or bearing faults. This preemptive approach is a cornerstone of intelligent electric motor repair strategies.

We value the integrity of your operations as much as you do.

Laser Shaft Alignment:

Precision Alignment for Peak Performance

Precision laser shaft alignment is paramount in maintaining the integrity of electric motor operations. Laser shaft alignment is at the forefront of achieving this level of reliability. Misalignment can cause excessive vibration, bearing wear, coupling stress and energy toss, leading to premature failure of the electric motor, coupling, and driven equipment.

Incorporating laser shaft alignment into regular electric motor repair and preventative maintenance schedules ensures that all components ,ire aligned to exact specifications. This high-precision technique not only enhances the efficiency and lifespan of your electric motors but also significantly reduces the risk of costly downtime.

Utilizing Pruftechnik RoAlign Ultra IS machines; state-of-the- art laser technology, skilled and certified RMSC/Industrial Service Solutions technicians can diagnose and correct misalignments and soft foot conditions with unparallel ed accuracy, making it a critical component of our electric motor repair services.

Cooling Systems: Protecting Electric Motors from Heat Damage

The cooling system of an electric motor is its first line of defense against the destructive forces of heat. Ensuring these systems are free from blockages and in good working order is critical for the longevity of the motor. Effective maintenance of cooling systems is a key service in the realm of electric motor repair.

RMSC/Industrial Service Solutions technicians can provide this service on site or in shop on any size electric motor.

Contact RMSC/Industrial Service Solutions to schedule service today.

AIR COMPRESSOR SALES, SERVICE, AND REPAIR

AIR COMPRESSOR SALES, SERVICE, AND REPAIR

RMSC/Industrial Service Solutions also is an industry leader in Air compressor s and compressed air system sales and service. As a Chicago Pneumatic distributor in the Rock Mountain region.

RMSC/Industrial Service Solutions can quickly respond to service calls emergency or scheduled throughout the front range.

RMSC/Industrial Service Solutions stocks Chicago Pneumatic

QRS 5.5 TM, QRS 5.5D TM, QRS 7.5 HD, QRS 7.5 HPD TM, QRS 10 125 TM, QRS 10D 125 TM, QRS 15 125 TM, QRS 15D 125 TM, QRSM 20 TM, QRSM 20D TM, and many reciprocating air compressors as well.

RMSC/Industrial Service Solutions does not stop there, large base mount QRS models are just a phone call away as well. Air-Net high capacity total compressed air distribution systems can be specifically engineered for your operation as well.

Call RMSC/Industrial Service Solutions today to assist with any compressed air or air compressor need!

Predictive and preventative maintenance:

A PROACTIVE APPROACH

Predictive maintenance: A thorough testing and monitoring regime, invaluable for potential electric motor issues the regularly scheduled vibration analysis an incorporated within a predictive maintenance program is invaluable. Incorporating advanced diagnostics and regular performance evaluations into your maintenance schedule can catch problems early, allowing for swift and effective electric motor repair actions.

Preventative maintenance: Beyond lubrication and general maintenance, where applicable, laser shaft alignment and dynamic balancing should be considered at intervals that make sense for the type of equipment, duty cycle, and environment the equipment operates within. Lowering

unnecessary forces caused by imbalance and shaft mis-alignment will greatly contribute to the reliability and longevity of that equipment life.

By under standing and implementing these key maintenance strategi es, plant and facility manager s can ensure their electric motor s operate with efficiency and depend ability. Regular maintenance not only saves on costly repairs but also ensures that electric motors – the workhorses of the industry- keep your operations running smoothly.

For expert assistance with electric motor repair, bearing replacement , dynamic balancing , vibration analysis , laser shaft alignment and air compressor repair, trust in our team at RMSC/Industrial Service Solutions.

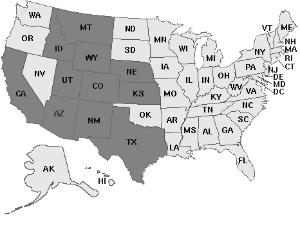

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states:

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states: