Unraveling Bearing Problems: Causes, Diagnosis, and Solutions

Bearing problems are a critical concern in industrial operations, where equipment reliability directly impacts productivity and costs. Whether it’s excessive vibration, overheating, or premature wear, addressing bearing issues quickly is essential to keeping machinery running efficiently. Let’s delve into the common causes, symptoms, and actionable solutions for bearing problems, ensuring your equipment’s longevity and optimal performance.

What Are Bearing Problems?

Bearings are the unsung heroes of industrial machinery health, reducing friction and enabling smooth rotational motion. When they fail, the ripple effects can disrupt production, increase downtime, and lead to costly repairs. Research shows that over 40% of machine failures in industrial environments are linked to bearing issues, often due to improper maintenance or contamination.

Speak with an expert TODAY! 303-594-7610

Need a QUOTE? Click Here

Got QUESTIONS? Email: service.0400@iss-na.com

Symptoms of Bearing Problems

1. Excessive Noise:

Grinding, squealing, or rattling sounds often signal wear or improper lubrication.

2. Vibration:

Abnormal vibration can indicate misalignment, imbalance, or internal bearing damage.

3. Overheating:

High operating temperatures suggest inadequate lubrication or excessive loads.

4. Premature Wear:

Visible scoring, pitting, or discoloration on bearings points to poor installation or contamination.

5. Corrosion

Rust and moisture damage occur when bearings are exposed to harsh environments or improper storage conditions.

Causes of Bearing Problems

1. Inadequate Lubrication

Lubrication is the lifeblood of bearing performance. Without it, friction increases, causing overheating and wear. Studies reveal that over 50% of bearing failures are attributed to lubrication issues.

2. Contamination

Contaminants such as dirt, dust, and moisture can infiltrate bearings, leading to corrosion and premature failure.

3. Improper Installation

Even a slight misalignment during installation can lead to significant issues over time.

4. Excessive Loads

Bearings are designed to handle specific load capacities. Overloading can cause deformation and early wear.

5. Environmental Factors

Exposure to corrosive substances or extreme temperatures can degrade bearing performance.

Diagnosing Bearing Problems

Diagnosing bearing problems requires a systematic approach:

- Visual Inspections: Check for wear, scoring, or discoloration.

- Vibration Analysis: Use tools to detect abnormal patterns.

- Temperature Checks: Identify overheating with infrared thermometers.

- Lubricant Analysis: Examine lubricants for contamination or depletion.

Solutions for Common Bearing Problems

Proper Lubrication

Use the correct lubricant and follow manufacturer guidelines.

Clean Environments

Maintain clean workspaces during maintenance and use protective seals.

Precision Installation

Ensure bearings are aligned and seated correctly using proper tools.

Load Management

Verify bearings are operating within their load limits.

Preventive Maintenance Programs

Implement regular inspections and monitoring schedules for our preventative maintenance program.

Condition Monitoring

Invest in tools like vibration sensors or thermal cameras for real-time insights.

Bearings as the Heart of Machinery

Think of bearings as the heart of your industrial machinery. Just like a heart pumps blood to keep the body alive, bearings reduce friction to keep your equipment running smoothly. Regular checkups and proper care can keep both in peak condition.

FAQ: Bearing Problems

- What causes most bearing failures? Lubrication issues, including under-lubrication or contamination, account for over half of all bearing failures.

- How can I prevent contamination in bearings? Use protective seals, maintain clean environments, and store bearings properly.

- How often should bearings be inspected? Regularly, depending on operating conditions and load.

- Can damaged bearings be repaired? Minor damage can sometimes be repaired, but replacement is often more reliable.

- What is the best lubricant for bearings? Consult manufacturer recommendations for the optimal choice.

Contact ISS/RMSC Today

Rotating Mechanical Solutions (RMSC) specializes in diagnosing and repairing industrial equipment, including bearing systems. Our expert team ensures minimal downtime and maximum performance, addressing challenges like overheating and vibration with precision and expertise.

Contact us today at 303-594-7610, visit RMSCcolorado.com, or email us at service.0400@iss-na.com.

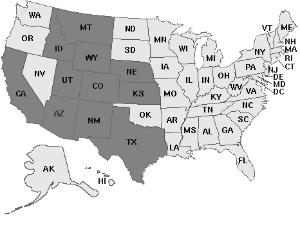

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states:

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states: