Importance of Adhering to Manufacturer Guidelines for Rotating Equipment Safety

Following manufacturer guidelines is the first step in ensuring rotating equipment safety. These guidelines offer essential instructions for installation, startup, shutdown, maintenance, and safety precautions specific to the equipment.

Why It Matters: Adhering to manufacturer guidelines helps prevent accidents and ensures that equipment operates within safe parameters.

Tip: Regularly review and update these guidelines to maintain the highest safety standards.

Stat: According to OSHA, 75% of rotating equipment accidents are due to non-compliance with manufacturer guidelines.

Operating rotating equipment safely is essential to prevent accidents, protect personnel, and maintain the integrity of machinery.

This guide from ISS / Rotating Mechanical Solutions (303) 594-7610 in Englewood, Colorado, provides detailed insights into best practices, safety protocols, and preventive measures for rotating equipment safety.

Comprehensive Training for Safe Operation of Rotating Equipment

Proper training is critical for all operators and maintenance personnel working with rotating equipment.

Training Topics:

- Safe operating procedures

- Emergency protocols

- Hazard identification

- Equipment-specific knowledge

Benefit: Comprehensive training reduces the risk of human error and enhances overall safety in your organization.

Tip: Schedule regular refresher courses to keep the team updated on the latest safety practices.

Proper Use of Personal Protective Equipment (PPE) for Rotating Equipment Safety

Personal protective equipment (PPE) is crucial when working with or near rotating equipment.

Types of PPE:

- Safety glasses

- Gloves

- Hearing protection

- Safety shoes

Benefit: Proper use of PPE significantly reduces the risk of injuries from accidental contact with moving parts.

Tip: Conduct regular PPE audits and ensure all employees are trained in the correct usage.

Think of PPE as the armor a knight wears—without it, they’re vulnerable to harm, just like workers without PPE around rotating machinery.

Lockout/Tagout Procedures: A Key to Rotating Equipment Safety

Lockout/Tagout (LOTO) procedures are vital for isolating energy sources before performing maintenance on rotating equipment.

Importance: LOTO prevents accidental startup of the equipment, protecting personnel from severe injuries.

Tip: Develop and implement a detailed LOTO procedure specific to each piece of equipment.

Stat: The National Safety Council reports that proper LOTO procedures can prevent an estimated 120 fatalities and 50,000 injuries annually.

Regular Inspections and Monitoring for Rotating Equipment Safety

Regular inspections are essential to detect any signs of wear, damage, or abnormalities in rotating equipment.

Inspection Focus Areas:

- Wear and tear

- Vibration levels

- Noise emissions

Benefit: Early detection through inspections prevents costly repairs and unplanned downtime, ensuring continuous and safe operation.

Tip: Implement a standardized checklist for all inspections and condition monitoring.

Ensuring Proper Guarding and Protective Barriers for Rotating Equipment Safety

Physical guarding is necessary to prevent accidental contact with moving parts of rotating equipment.

Types of Guards:

- Fixed guards

- Interlocked guards

- Adjustable guards

Benefit: Proper guards reduce the risk of injury and ensure compliance with occupational safety regulations.

Tip: Regularly inspect all guards for damage and wear, and ensure they are always in place.

Monitoring Operating Parameters to Enhance Rotating Equipment Safety

Continuously monitoring operating parameters such as temperature, pressure, flow rate, and vibration is crucial for rotating equipment safety.

Why It Matters: Deviations from normal ranges can indicate potential problems that require immediate attention.

Tip: Utilize real-time monitoring systems and set up alerts for when parameters exceed safe limits.

Implementing and Maintaining Safety Interlocks for Rotating Equipment

Safety interlocks are essential for automatically shutting down rotating equipment under abnormal conditions.

Benefit: These interlocks act as a safeguard against catastrophic failures, protecting both personnel and equipment.

Tip: Regularly test and maintain safety interlocks to ensure they function properly.

Keeping Workspaces Clear and Organized for Rotating Equipment Safety

A clutter-free workspace is essential for the safe operation of rotating equipment.

Why It Matters: Clear workspaces reduce the likelihood of accidents and make emergency responses easier.

Tip: Implement a 5S (Sort, Set in Order, Shine, Standardize, Sustain) approach to workspace organization and conduct regular housekeeping audits.

Periodic Safety Training and Reviews to Maintain Rotating Equipment Safety

Continuous safety training and regular safety reviews are crucial for maintaining a safety-first culture.

Benefit: Regular training keeps personnel updated on the latest safety practices and helps identify any areas for improvement.

Tip: Schedule regular safety meetings and drills, encouraging open discussions about safety concerns.

FAQ on Rotating Equipment Safety

What is rotating equipment safety?

Rotating equipment safety involves best practices, procedures, and guidelines to prevent accidents and ensure the safe operation of machinery with rotating parts.

Why is PPE important for rotating equipment?

PPE protects workers from potential hazards, such as contact with moving parts, by providing a physical barrier that minimizes the risk of injury.

How often should rotating equipment be inspected?

Rotating equipment should be inspected regularly, typically before each use and during scheduled maintenance, to detect any signs of wear or damage early.

What are lockout/tagout procedures?

Lockout/tagout procedures isolate energy sources and prevent accidental startup during maintenance, protecting workers from severe injuries.

Promoting a Culture of Safety in Rotating Equipment Operations

At ISS / Rotating Mechanical Solutions, we prioritize rotating equipment safety to protect our team and ensure efficient operations. By following these best practices, your organization can mitigate risks, safeguard personnel, and maintain the integrity of your equipment.

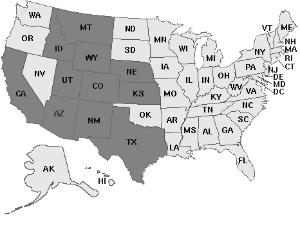

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states:

ISS/Rotating Mechanical Solution proudly provides Industrial Equipment Solutions for our customers in the following states: