Predictive and Preventative Maintenance

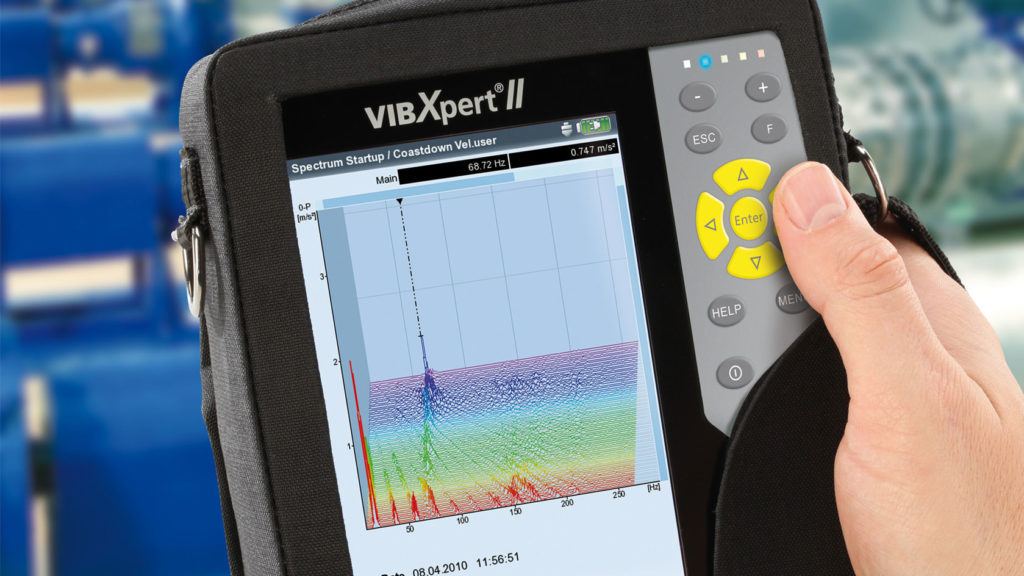

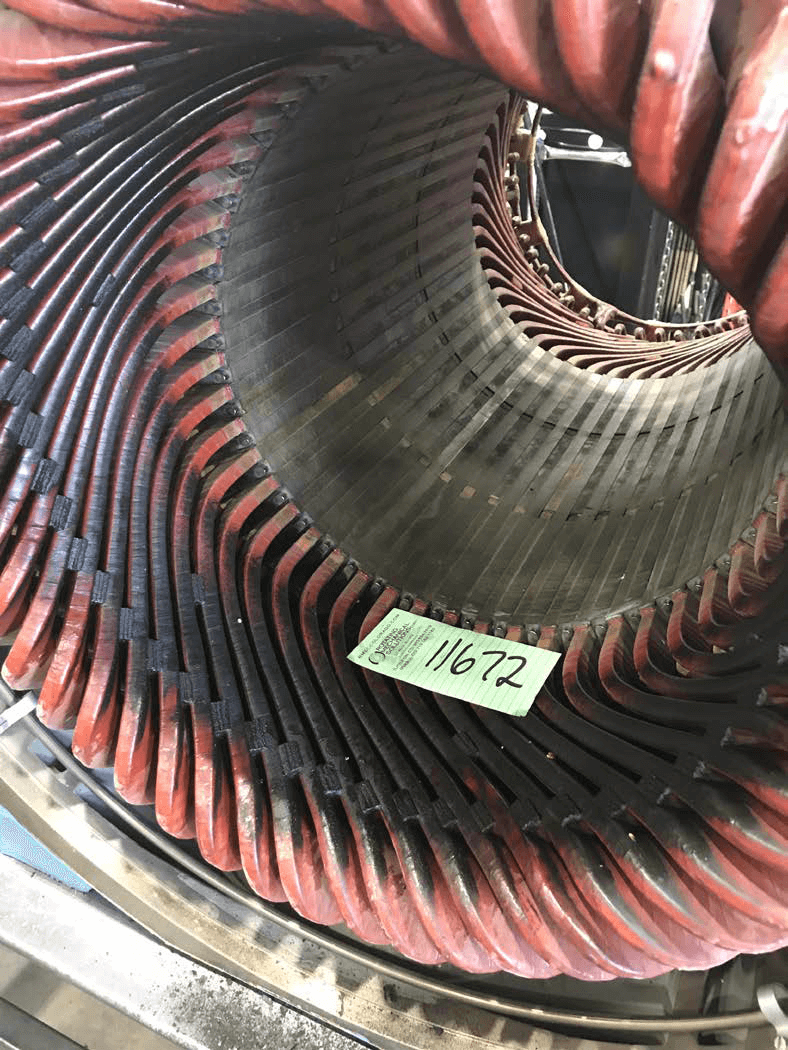

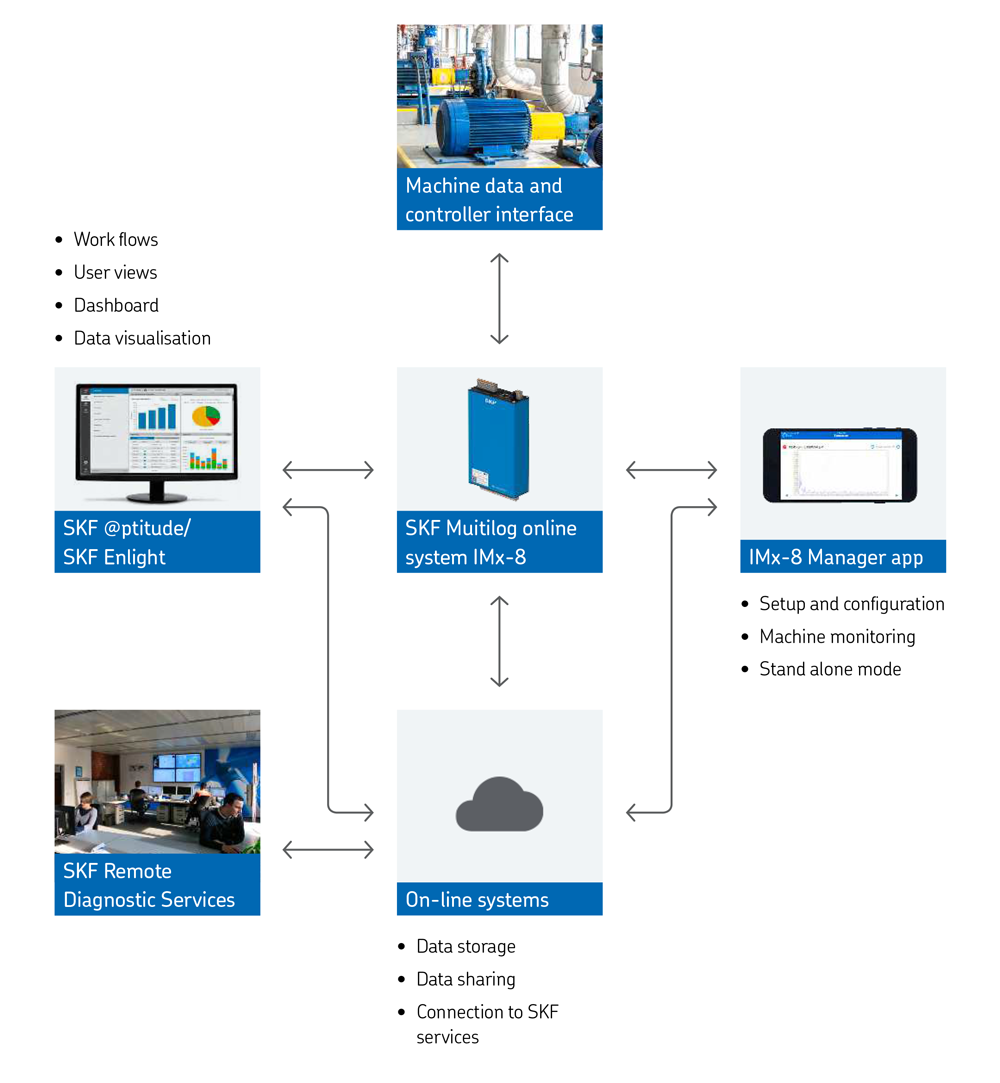

Rotating Mechanical Solutions Corp. offers a full line of state-of-the-art equipment to perform services including vibration analysis, laser shaft alignment with Live Trend capability, laser belt alignment, laser roll alignment, ultrasonic testing, infrared thermography, on-site electric motor evaluation with online and offline testing capabilities, and dynamic balancing both on-site and in the shop on our high-speed balancing stand.

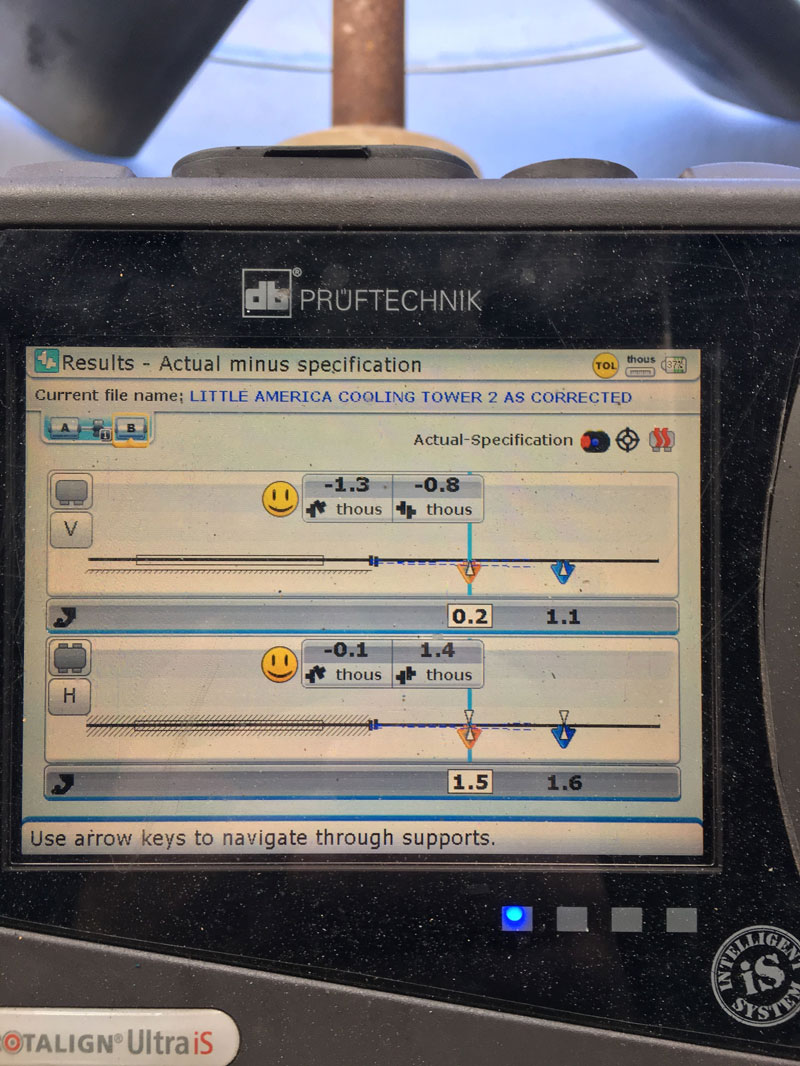

Laser Shaft Alignment

Having optimum facility production and reliability starts with proper equipment installation and setup, as well as performing regular maintenance. Using the Rotalign Ultra iS, we perform precision laser shaft alignments and provide reports for your documentation that indicate initial misalignment and the actions taken to correct it. From start-ups and annual alignment verifications on multi-thousand horsepower compression equipment in the gas and oil fields to critical equipment such as fire pumps and chilled water pumps in buildings downtown, RMSC will enhance equipment operation, reducing downtime and costly repairs.

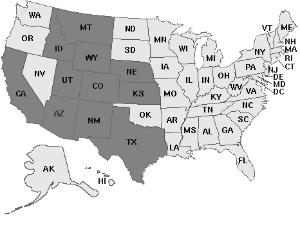

Rotating Mechanical Solutions Corp. proudly provides Industrial Equipment Solutions for our customers in the following states:

Rotating Mechanical Solutions Corp. proudly provides Industrial Equipment Solutions for our customers in the following states: